Wet Bearing Protection

The main failure mode in wet applications for vacuum motors is grease washout of the working end bearing. For years, the traditional designs would only yield 100 hours of life during the notable "suds" test, until Bison® invented the bearing air seal. This innovation increased the life during the same test to 250 hours.

The main failure mode in wet applications for vacuum motors is grease washout of the working end bearing. For years, the traditional designs would only yield 100 hours of life during the notable "suds" test, until Bison® invented the bearing air seal. This innovation increased the life during the same test to 250 hours. Still, 250 hours was not acceptable for the commercial marketplace where downtime costs money. Additionally, Bison engineers added a rotating seal for protection and enhanced life.

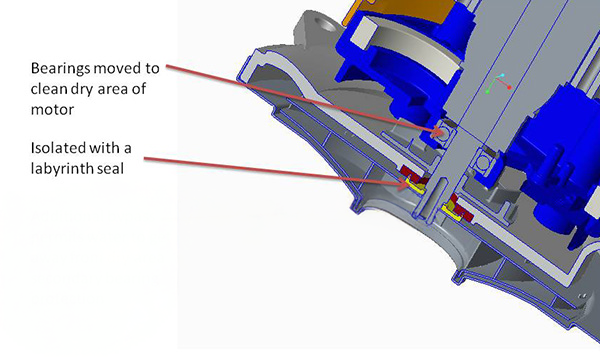

With Bison's latest wet bearing protection, the vacuum motors no longer fail due to moisture washing away grease from the bearings. The technology required a redesign and a bit of ingenuity.

- We moved the bearing away form the moisture by removing it from the fan system.

- We installed a labyrinth seal to provide a barrier for the moisture in the fan to the bearing.

- We removed the cooling fan from the traditional side of the motor down to its base. If water makes its way past the labyrinth seal, it will be whisked away.

Engage with our engineers, locate an authorized distributor or connect with customer and technical support.

Find a product

Find a product