Chemical Processing Blowers: Corrosion-Resistant Solutions for Harsh Environments

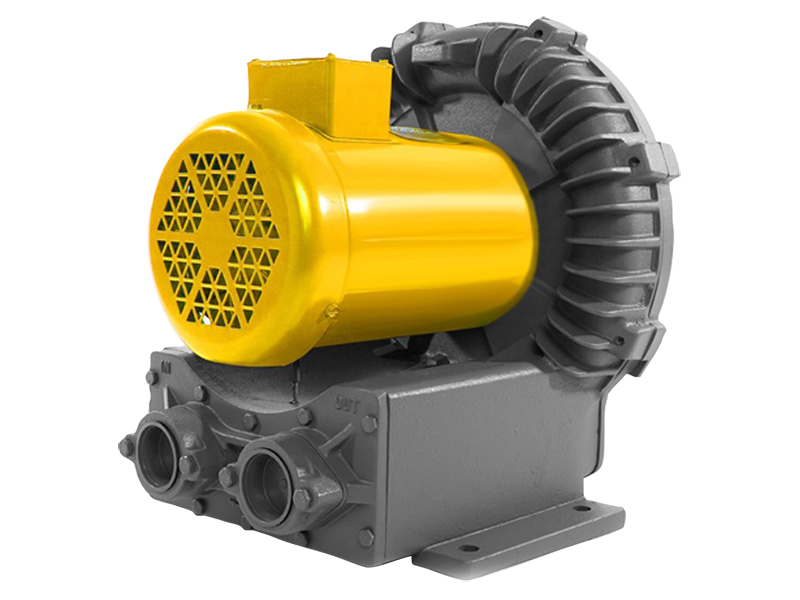

Bison's extensive lineup of ROTRON Regenerative Blowers, including chemical processing (CP), industrial (DR), environmental (EN), remote drive, and application-specific blowers like those for spas, offers unmatched versatility and reliability.

Designed with customer needs in mind, our blowers incorporate advanced motor options and innovative features to tackle even the most demanding applications.

For chemical processing environments, our blowers stand out thanks to the Chem-Tough process, which delivers superior chemical resistance, durability, and performance. With a full range of standard features and customizable sealing options, Bison's chemical processing blowers are engineered to excel in corrosive and hazardous environments, ensuring long-lasting and efficient operation.

Why Choose CP Blowers?

• Gases or the environment are corrosive to product components.

• Gases are hazardous or corrosive to the environment.

• Different sealing options are required. (Face seal, Nitrogen Purge, Engineered Seal)

• Sanitary Applications

• Shaft end play, runout, and perpendicularity requirements above NEMA standards

• CE conformity (Non-XP models)

• Single shafted totally enclosed fan-cooled (TEFC) and explosion-proof (XP) models

• UL and CSA approved

• Permanently sealed bearings• Dual voltage and dual frequency to maximize use worldwide.

• Double Shafted Open Drip Proof (ODP) models with dual internal fans for circulation

• Class I Group D minimum on explosion-proof motors; many are Class I Group D, Class II F and G

Typical Sealing Options:

Lo-Leak Lip Seal: The Lo-Leak Lip Seal option is available to control gas leakage; it is standard on ROTRON Chemical Processing Regenerative Blowers. The lip seals prevent leakage to the motor shaft mating surfaces sealed with high-temperature RTV. The castings are vacuum impregnated to prevent leakage through the castings.

For further minimization of gas leakage on all CP models, a pair of face seals work against each other on opposite sides of a common mating ring to effectively reduce gas leakage at the motor shaft. The face seals are continually lubricated from a reservoir housing to prolong seal life.

The seal is completed by installing the blower-to-motor bolts with O-rings and sealing the covers to the housing with an RTV sealing compound. O-rings are also placed between the flanges. All our castings are vacuum-impregnated.

Hermetically Sealed Mag Drive Option: On our MD101 and MD303 units, a magnet-magnetic drive option has been an alternative for complete gas containment. O-rings are used throughout the product. Magnets are attached to the motor shaft to spin magnets inside the blower—without shaft penetration.

Nitrogen Purge/Blanket Option:The nitrogen purge option is a carrier designed to accept a nitrogen line that will purge the space around the shaft. Purges can be designed to bleed the nitrogen into the process called a blanket, or the carrier can have a second tap to carry away the leaking contaminants.

The Most Chemical-Resistant Blowers on the Market

Chem-Tough Chemical Resistance: To stand up in corrosive and hazardous environments, chemical processing blowers have to be tough. That's why Bison routinely applies its proprietary Chem-Tough process whenever blowers are manufactured to handle chemical (vapor) streams. Chem-Tough combines aluminum oxide ceramic and selected fluorocarbons to give ROTRON CP Regenerative Blowers unparalleled chemical resistance, hardness, abrasion resistance, permanent lubricity, and more.

Chem-Tough at Work: Chem-Tough employs the advantages of anodizing, hard coat plating, low-friction polymers and dry lubricants to become an integral part of the blower's molecular structure. Specifically, Chem-Tough first converts the aluminum surface to aluminum oxide, forming a new ceramic-like surface.

The water in the ceramic is replaced with Teflon, adding a multi-functional dimension to the surface. In the process, the aluminum crystals expand and form anchor crystals that remain hygroscopic for a short time. Then, under controlled conditions, particles of the specified polymer are infused to interlock with these anchor crystals.The new surface extends .5 mil above and below the original aluminum surface—and forms a permanent molecular bond with the metal. The result is a plastic/ceramic surface that's harder than steel, is continuously lubricating, and resists damage from chemicals like no other. This is the kind of protection you need for your chemical processing blowers.

Through this unique proprietary process, Chem-Tough gives ROTRON CP Regenerative Blowers these advantages:

-

Outstanding Chemical Resistance: Time after time, Chem-Tough finishing shows extremely high resistance to most common chemicals, as well as dramatically improved corrosion resistance over regular hard anodizing. Chem-Tough allows aluminum to achieve an equivalent corrosion resistance as Teflon. 90-day immersion in acid or alkaline solution (pH 4.0-8.5) has no effect; neither does prolonged exposure to salt water. The Chem-Tough solution far exceeds military specification requirements for salt spray.

-

Abrasion Resistance Equivalent to Steel: Excellent for smooth surfaces, Chem-Tough surface conversion provides higher wear resistance than either case-hardened or hard-chrome plate. Rub any other metal against the Chem-Tough finish, and the metal will show nothing but the slightest wear. Chem-Tough provides a perfect bond to the parent metal.

- Increased Hardness: With an equivalent hardness of Re 40-60, Chem-Tough is approximately file hard, the hardness of nitrated steel. Because the Chem-Tough surface becomes an integral part of the metal, it simply cannot peel or chip; neither can it be scratched, flaked, or nicked under ordinary circumstances.

- Permanent Dry Lubricity: By infusing polymers into aluminum, Chem-Tough gives the resulting surface a high degree of permanent dry lubricity and resistance to moisture. The polymers also level off surface asperities, significantly reducing surface tension. The result: Chemical Processing Blowers converted with Chem-Tough have a longer life, operate more efficiently, and require less maintenance.

| Application Include | |

|---|---|

| Agricultural | Environmental |

| Foundry | Manufacturing |

| Refineries | Air Pollution Control |

| Instrumentation | Plastics Handling |

| Water Pollution Control | Material Handling |

| Packaging | Pharmaceutical |

| Aqueous Precision Cleaning |

|

Find a product

Find a product